How We Innovate

OUR CREED OF DEVELOPING NEW PRODUCTS IS "CUSTOMER'S VOICES FROM THE FIELD."

With our original technologies, we will continue creating new products that will lead the next generation.

While strictly sticking to our jobsite-oriented principle, we create "products only we can create" in a new product development process supported by our development environment. The process starts from formulating plans and concepts by merging needs and our own technologies.

Furthermore, we maintain the position of selling "our unique and quality products" with technologies that enable us to create sales points in our products, and intellectual property rights.

Development Prosess

Create new value from the opinions of customers

Our planners and machine/hardware/soware designers visit workplaces around the globe in order to understand the customers' needs and their working environments. They expand their ideas from the perspective unique to engineers, and create new value.

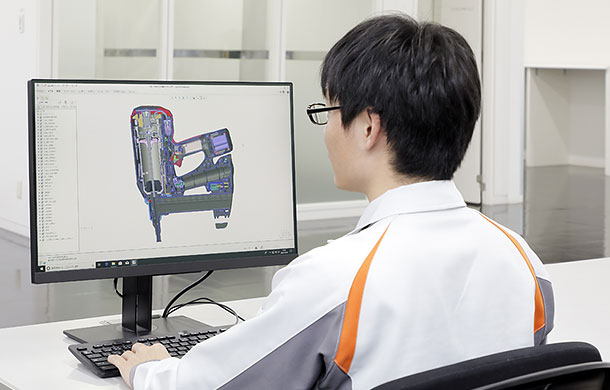

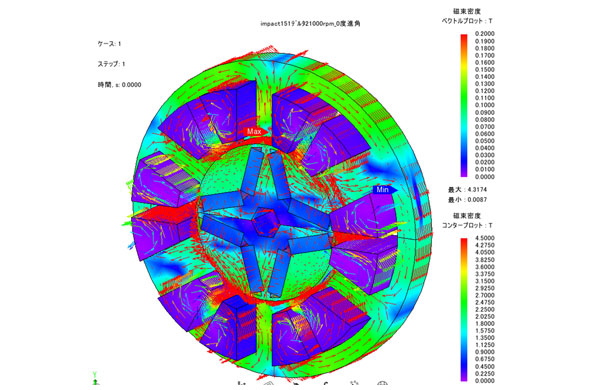

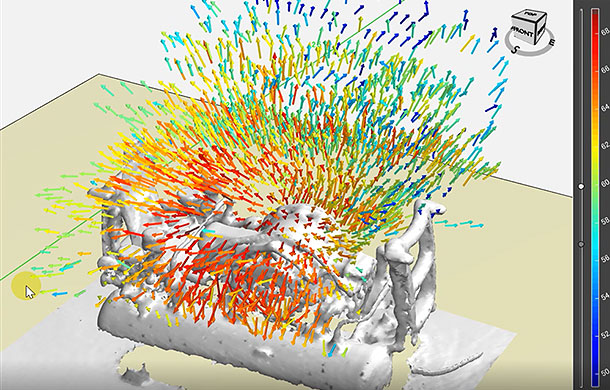

Integration of machine/hardware/soware design and analysis-led design

Machine/hardware/soware designers work together to solve tasks from multiple perspectives, and improve product quality.

In software development, we consider machine control to be our starting point, and then add necessary cutting-edge technologies such as IoT, cloud computing and web/mobile applications to create new customer value.

Trial manufacturing/measurement/evaluation supported by the latest industry equipment

We have introduced a variety of the latest devices for experimental manufacturing and measurement,such as metal 3D printers and 3D scanners. Such devices support our technological research and the development of new products.

In addition to temperature and humidity environmental tests, we have established an evaluation system for situations in which our products are placed in harsh environments with dust, heat, humidity and cold.

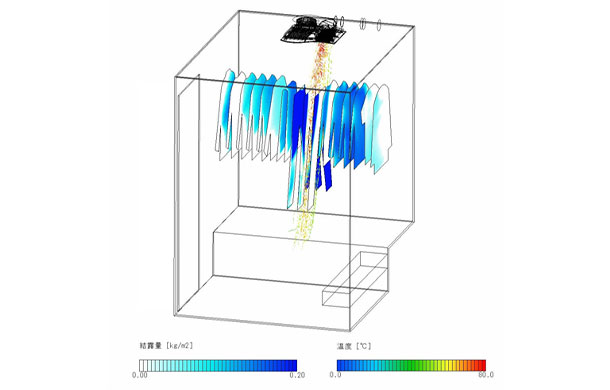

We are able to support high quality products by quantitatively evaluating diicult sources to measure such as sound sources, image quality, and drying performance by utilizing advanced analyzing techniques to quantify and visualize them.

Our products are sold worldwide and used in various workplaces.

We utilize the niche-top strategy in which we protect our unique products created by merging core technologies and needs with intellectual property rights

WORLD-LEADING FACILITIES WITH WORLD-LEADING MANUFACTURING SYSTEMS

MAX's trusted and globally competitive products are manufactured in world-leading facilities with world-leading manufacturing systems.

Our consumables are produced on production lines which are mainly constituted from in-house developed equipment and require few or no operating personnel, thus achieving high productivity and maintaining a clean operating environment.

The main precision parts are produced by the latest processing machines, and are controlled and operated effectively. Our trusted and globally competitive products are produced by such facilities and production systems. We achieve our responsibility to deliver products that satisfy our customers by building and advancing our quality control system, which needs to be able to be flexible in order to fulfil the diverse needs of the market. This is done by having our team members learn from the market by practicing the "Principle of three realities" (go to the actual place, know the actual situation and be realistic).

Tamamura Factory

"Flexible manufacturing factory" that responds to changes in demand in a timely manner.

The Tamamura Factory is our main factory for industrial equipment, where the entire process of manufacturing nailers, from processing to assembly, is conducted.

To respond to diversified market needs, we have turned this factory into a facility where we can produce various kinds of products in any quantity, and the factory now produces about 200 types of nailers, gas nailers, rebar tying machines, etc.

Toward the improvement of supply chain management, we are promoting the highly efficient and flexible production of high-quality products by implementing CNC machining controls based on our own engineering and cell manufacturing method.

This is a mechatronics factory which also manufactures compressors, power tools,office machines such as Bepop and label printers as well as auto staplers, and serves as the main factory of MAX.

Fujioka Factory

World's top-notch factory dedicated to manufacturing consumables.

Our Fujioka Factory is one of the largest factories in the world dedicated to manufacturing consumables, both in terms of facility size and production amount.

The factory manufactures staples for oice equipment and industrial equipment as well as wires for rebar tying tools (TIE WIRE). It also actively works on developing new consumables such as high-precision staples for auto staplers, and promotes technological innovation in the production and product development of new consumables. Furthermore, the factory has an integrated manufacturing system covering processes from material processing to finishing, which is composed of in-house developed facilities.

In Fujioka Factory, high level automation of product manufacturing is already achieved: while products are automatically manufactured by the equipment in this factory, human workers

concentrate on set-up changes, quality management and maintenance.

Yoshii Factory

We established a production system by integrating manufacturing and logistics functions for housing environmental equipment

Our Yoshii Factory produces electric heater/dryers for bathrooms, which have a market share of about 50%, as well as heat exchange type 24-hour ventilation systems and disposers.

The factory is equipped with "a line for housing environmental equipment to pack assortments of equipment for each household, "which has improved the eiciency of "picking and small-lot packing work." The factory also contributes to improving the productivity of logistics work as a whole.

Kuragano Factory

Our Kuragano Factory manufactures small staplers as well as tanks for air compressors.

With its in-house developed production facility, manufacturing processes from press processing to assembly are automated. With automated lines equipped with functions such as in-line automatic inspection, a high quality and highly eicient mass production system is established at this factory.