Environmental Management

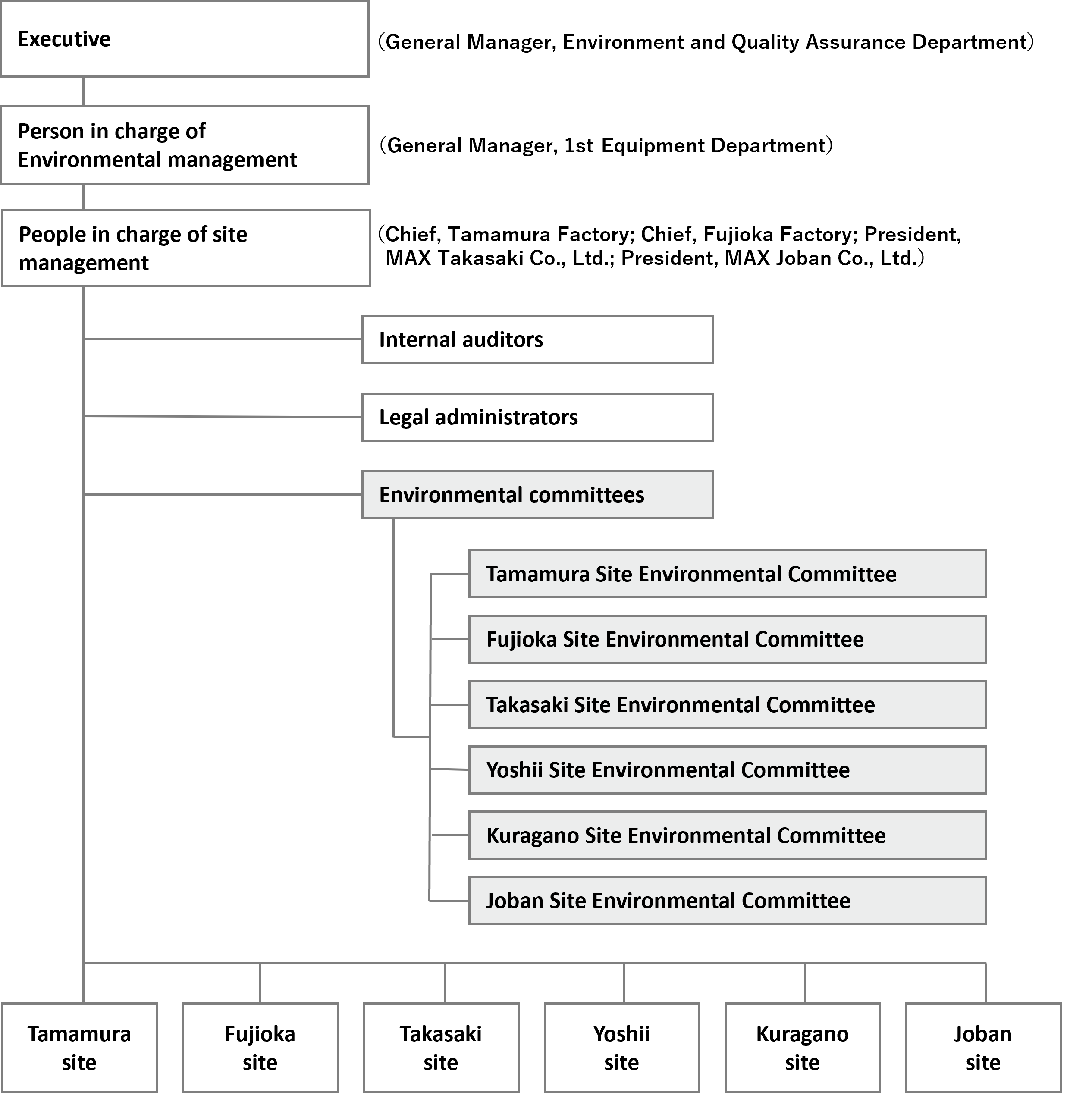

Based on the MAX Environmental Declaration and Basic Environmental Guidelines, MAX has set up an EMS Committee chaired by the General Manager of the Environment and Quality Assurance Department. Environmental committees promote activities at each manufacturing site to reduce the environmental burden.

MAX Environmental Declaration

Providing environment-friendly products and services is the starting point for MAX's goal of creating customer value. In essence, it is the very practice of "To take responsibility in supplying quality products" as stated in the MAX Company Creed.

We have established the following Basic Environmental Guidelines as a code of conduct in environmental conservation efforts related to all of the MAX Group's corporate activities. We will work on environmentally-friendly manufacturing, and aim to achieve harmony between our business and the environment.

Basic Environmental Guidelines

- 1We will strive to reduce the environmental burden through actions such as conserving resources, saving energy, reducing harmful substances, and decreasing the amount of waste, at each stage from product planning, development, and design to production, distribution, use, and disposal.

- 2We will comply with environmentally-related laws, regulations, etc., establish voluntary standards, etc., and strive to improve management.

- 3We will continue to carry out in-house public relations and education for raising environmental awareness so that each employee engages in environmentally-friendly behavior.

- 4To implement these guidelines, we will set environmental objectives and targets, and promote a positive cycle of improvement activities.

- 5As necessary, we will disclose the implementation status for development and management of environmentally-friendly technologies, materials, products, services, etc.

Organization of EMS (Environmental Management System) Committee

Acquisition of ISO 14001 Certification

MAX has acquired ISO 14001 certification at all domestic manufacturing sites in Gunma Prefecture (Tamamura*, Fujioka, Takasaki, Yoshii, Kuragano) and Ibaraki Prefecture (Joban), as well as overseas factories in China (Shenzhen), Malaysia, and Thailand.

- *Includes MAX Logistics Warehouse Co., Ltd.

| Domestic Bases | |||

|---|---|---|---|

| Date of Recording Certification |

Details | Application Site | Applicable Office / Related Company |

| June,1999 | Acquisition of ISO 14001:1996 | Tamamura site |

|

| February,2000 | Acquisition of ISO 14001:1996 | Takasaki site |

|

| February,2001 | Acquisition of ISO 14001:1996 | Fujioka site |

|

| June,2002 | Integration of three sites | Tamamura site Takasaki site Fujioka site |

|

| June,2008 | Acquisition of ISO 14001:2004 Additional sites | Yoshii site |

|

| June,2017 | Acquisition of ISO 14001:2015[Update] | Tamamura site Takasaki site Fujioka site Yoshii site |

|

| June,2017 | Acquisition of ISO 14001:2015 Additional sites |

Kuragano site |

|

| July,2018 | JQA Integration ProgramStage I |

Tamamura site Takasaki site Fujioka site Yoshii site Kuragano site |

|

| July,2020 | Additional sites | Joban site |

|

| July,2021 | organizational change | Tamamura site Takasaki site Fujioka site Yoshii site Kuragano site Joban site |

|

| July,2022 | JQA Integration Program Stage Ⅱ |

All site |

|

| July,2023 | JQA Integration Program Premium Stage |

All site |

|

| Overseas Bases | |||

|---|---|---|---|

| Date of Recording Certification | Details | Country Name | Applicable Office / Related Company |

| November,2006 | Acquisition of ISO 14001:2004 | China |

|

| July,2008 | Acquisition of ISO 14001:2004 | Malaysia |

|

| July,2017 | Acquisition of ISO 14001:2015 | Malaysia |

|

| October,2017 | Acquisition of ISO 14001:2015 | China |

|

| November,2019 | Acquisition of ISO 14001:2015 | Thailand |

|

- *1From FY 2002, the name of the Takasaki Factory was changed to the Takasaki Office.

- *2From FY 2016, MAX Service Co., Ltd. changed its name to MAX Engineering Services Co., Ltd.

Compliance with environmental laws and regulations

Each production base of MAX clarifies the related laws and regulations based on their production lineup, and complies with requirements.

- Planned improvement of energy eiciency based on the Energy Saving Act

- Regular measurement of air and water quality

- Appropriate disposal of waste

- Management of substances prohibited in products based on laws and regulations such as the EU RoHS directive

- Management of chemical substances based on the PRTR Law

Green Procurement

MAX has established the "MAX Green Procurement Standards" for chemical substances, etc., and is thoroughly observing them at our company and our suppliers.

| NO. | Document Name | Overview |

|---|---|---|

| 1 | MAX Green Procurement Standards | Record of purpose, scope of application, etc. |

| 2 | MAX Chemical Substance Management Standards | Description of list of chemical substances to be investigated and forms to be submitted |

| 3 | Survey guidelines for information on chemical substances contained in products | Description of survey contents on raw materials and auxiliary materials used by business partners |

| 4 | Guidelines for chemical substance management systems | Description of construction of a chemical substance management system for business partners |

Environmental Education

MAX conducts annual environmental education on energy, recycling, chemical substances, etc., for all employees at our manufacturing sites.

The Environment and Quality Assurance Department conducts specialist training and work training on legal regulations and behavior during emergencies, and also certifies qualifications based on plans for qualification and skill acquisition.

Internal Audits

We carry out periodic internal environmental audits at all of MAX's domestic manufacturing sites and in China (Shenzhen), Malaysia, and Thailand. Based on the ISO 14001 standard, we operate a PDCA cycle to confirm that the EMS (Environmental Management System) is functioning properly.